What is a reefer container, and how does it work?

A reefer container is a mobile refrigerator that can carry perishable merchandise across any country on the planet. A refrigerated container can transport frozen items, but it is also commonly used to transport dry commodities. Fruits (such as apples), meat (such as beef), seafood (such as tuna), vegetables (such as broccoli), dairy (such as cheese) and even non-food items like flowers, medications, and films are all examples of what might be included. Freight forwarders employ six different kinds of shipping containers, and this is one of them.

Reefer Containers are built like a giant refrigerator; and can typically sustain a temperature range of 30°C to -30°C. They must be integrated into the existing local or public supply chain, which is no small feat, even if the notion seems easy.

With a wide range of sizes, reefer containers may be transported by road, sea, and air. To establish distinct temperature zones, they might be divided. Frozen and chilled food can be stored in the same container.

Reefer containers have changed the transportation of temperature-controlled commodities since their introduction in the 1960s. Reefer containers are anticipated to play an essential role in the supply chain for enterprises that deal with perishable items.

Reefer containers are meant to keep the temperature, humidity, and environment of the container at a fixed value throughout the whole transport duration.

Temperature, humidity, ventilation, and drainage are all factors to consider while transporting a reefer container.

- Temperature: For chilled and frozen goods, all conventional reefer containers are always designed to maintain a temperature range of 30°C to -30°C. A small fraction of the world’s reefer fleet can operate at temperatures as low as -35°C. -70° C may be maintained in special containers (super freezers).

- Humidity: Some items are better served by a lower humidity level in the atmosphere. The dehumidification feature of a reefer container reduces the amount of moisture in the air. It’s very uncommon for newer devices to hit 50%, although the type is between 60% and 85% RH.

- Ventilation: To maintain a stable temperature, the cargo must be constantly exposed to fresh air to remove heat and gases. As a result, ventilation in reefer containers should be inbuilt. Fruits and vegetables need to be ventilated with fresh air. Air must circulate cargo if it is to remain frozen. It should be ensured that there are no significant gaps between the container, any adjacent walls, and the container itself. Storing goods in blocks is the preferred method.

- Drainage: These release excess water that may accumulate inside the containers. In addition, their design prevents water or insects from getting into the container.

How does a reefer container work?

Reefer containers are not self-sufficient and must be hooked into an electricity source to function correctly. A depot, terminal, ship, or a Genset can serve as this energy source.

Using T-shaped decking, the air is directed beneath the cargo in reefer containers, ensuring a constant and uniform airflow throughout the shipment, which is critical for proper air exchange with the contents. Reefer containers are bottom air supply units.

Shipments in reefer containers are kept cold, and, if needed, the temperature may be raised to a higher level. Using the container’s control unit, temperature, humidity, ventilation, and environment may be controlled and adjusted. Transportation of different types of goods necessitates a different set of parameters.

Reefer containers rely on a steady stream of power to perform these functions. The electricity comes from the vessel’s power outlet or portable generators known as “gensets.”

Using cargo probes to monitor the temperature of particular shipments is one option. The electronic temperature recorder is housed inside a microprocessor inside of the container. The temperature-sensitive element on one end of the examination is attached to the cable. The data on the temperature of your items may be accessed at any moment. Information like supply and return air temperature, distance to cargo probe and defrost activity, and any adjustments to the setpoint and times of start-up and shutdown are all saved in this device.

Temperature control is critical for fresh produce, especially for extending shelf life and ensuring high quality in a dependable and closed cold chain. In order to fulfil requirements and maintain product quality, temperature-controlled transportation is essential.

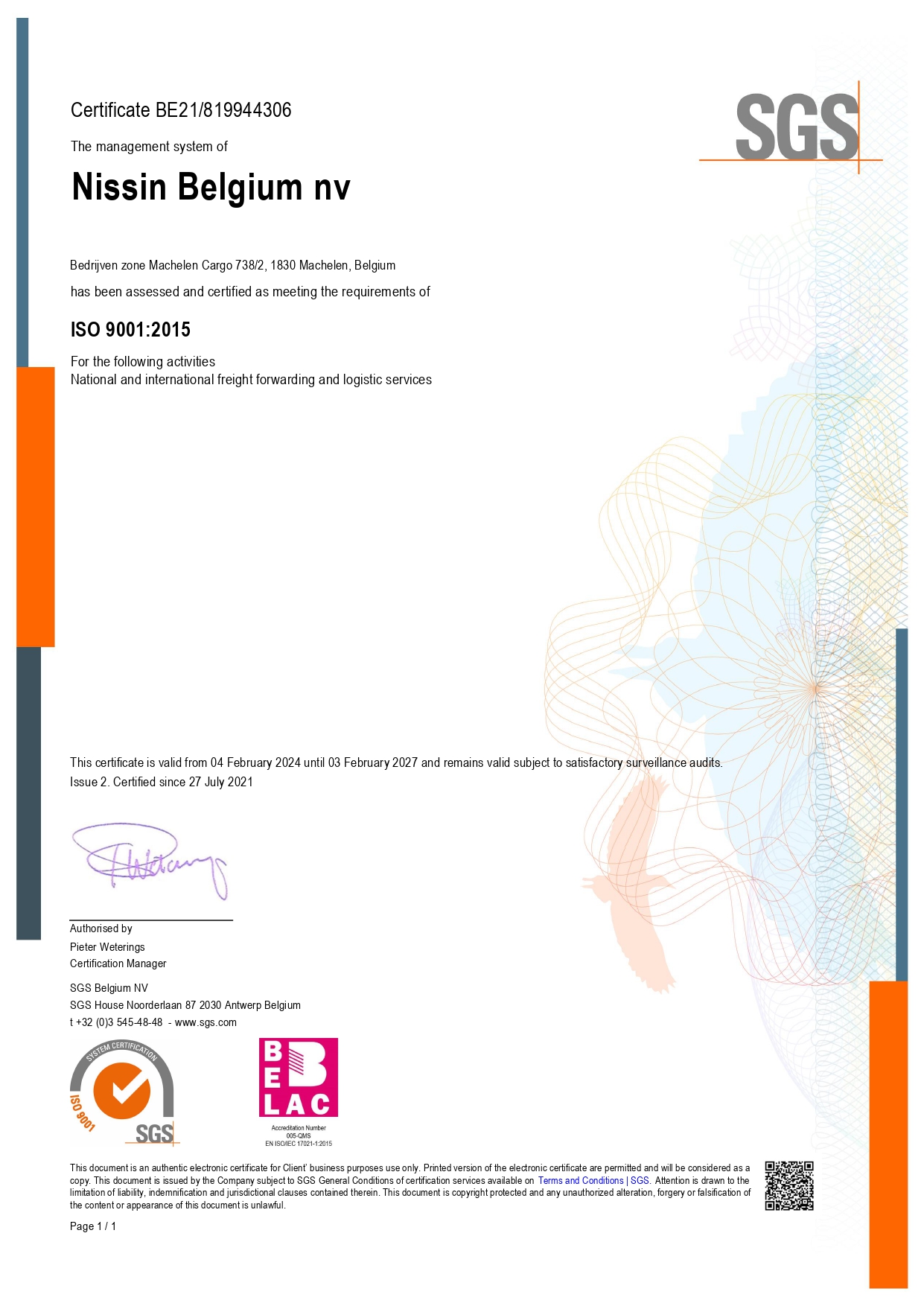

Temperature-controlled logistics are Nissin’s speciality, regardless of the mode of conveyance. For this reason, we only use the greatest equipment and collaborate with thoroughly vetted partners that use only the best temperature and humidity controls. As a result of this, your items will arrive on time, at the correct location, and at the proper temperature.

Your customised solution allows us to show off our strengths as architects at Nissin, because it blends adaptability, efficiency, and ergonomics. Our willingness to take on these challenges is a sign of our commitment to our clients.

To learn more about what Nissin can do for you as a third-party logistics (3PL) supplier, don’t hesitate to contact us at +3227514499 today.