6 Best Practices for Logistics in the Automotive Industry

Logistics in the automotive industry refers to the preparation and execution of the movement of automobiles and their components. Shippers can benefit from a 3PL’s technological developments in data, analytics, and service to facilitate more effective freight procurement. Logistics enhances automobile production, transport, and acquisition by providing more information about the entire automotive supply chain. The logistics of transporting vehicles also benefits from this. The ability to send and track packages is crucial to manufacturers, and logistics helps with this process.

The automotive industry is adapting rapidly to meet consumer needs, such as the growing popularity of electric vehicles and the need for more advanced digital navigation systems.

The six most critical aspects of automotive logistics management are as follows:

1. A good plan is essential.

It is necessary to carefully assign each plant’s capacity in addition to all the production resources, tools, and associated equipment. When there is not enough capacity, this might lead to bottlenecks. You can ensure that there will always be enough trained machine operators available to maintain appropriate power if you organize the shifts that machine operators work. Increasing the transparency of your production flows and providing a clearer picture of your complete logistics capabilities are potential benefits of digitizing them.

2. Appreciate and promote exceptional performance

The key to a successful logistics operation is finding the proper individuals to work in it. Skilled engineers allow you to adapt rapidly to meet the needs of your market. Spend money on your team to help them improve and grow. To get the best results, you need the best employees.

3. Administration of a storage facility

Changing to a “just-in-time” system may facilitate a more adaptable manufacturing setting and a quicker reaction time from the supply chain. You should investigate employing a third-party warehouse when you need more space to store automotive components and raw materials. The details are then sent to you “just in time,” taking up as much or as little room as you require.

4. Perform both measured and improvised performances.

Equipment and technology are equally as vital as, if not more so, the ways in which people collaborate and interact. They offer essential contributions to the field of logistics with both the systems and the analytics that they supply. Find the right individuals and service providers to carry out data analysis and decision-making so that you can keep one step ahead of any subsequent changes.

5. Quick and easy travel

You will only get the total value of your production system if you can transport your car parts or supplies quickly and easily. Transport efficiency can be improved in numerous ways, especially in light of the ageing of fleets and the shortage of drivers. Technology in truck cabs now allows for predictive management of a truck’s path, with data transmitted to the facility to notify workers of any delayed components. You need to know right away if a vehicle is late or if there is an issue. By acting on this information, you may swiftly manage and resolve the issue and keep the plant running.

6. Take into account the recent advances in technology and automation.

Investigate how your car parts are transferred from station to station along the production line. If you examine your production process in great detail, you should be able to find ways to optimize it and make it more efficient. You can accurately trace your products from when they are brought into the plant to when they are sent out if you use specialized software. Thanks to recent technological advancements, you can escape the hassle of having untrackable inventories or inefficient fulfilment operations.

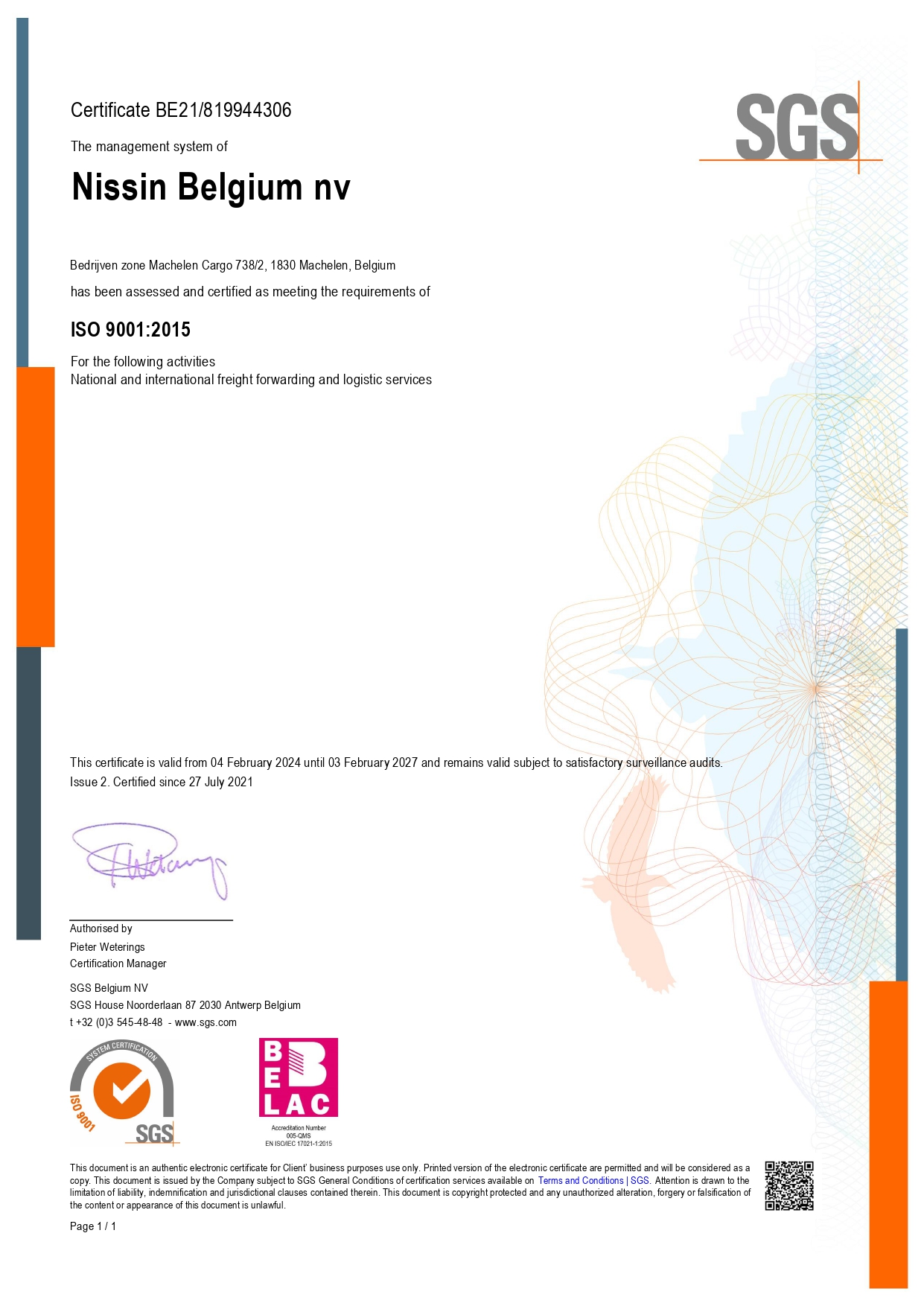

It is essential to evolve and get better if one wishes to succeed in a very competitive market. By emphasizing strategic automotive logistics solutions, Nissin can contribute to your supply chain’s efficient operation.