Lithium-ion batteries are essential to many modern devices, from smartphones to electric vehicles and renewable energy systems. However, shipping these high-energy power sources involves significant complexity. Because of their high-risk materials, lithium-ion batteries‘ transportation demands strict adherence to regulations, safety standards, and specific packaging guidelines.

We’ll learn factors to consider when shipping lithium-ion batteries, including regulatory requirements, proper packaging, and safety measures for secure transit.

What Makes Lithium Ion Batteries Dangerous for Shipping?

Lithium-ion batteries are classified as high-risk goods because they can overheat, catch fire, or even explode under certain conditions. Thus, shipping them is challenging and requires strict adherence to international regulations.

Furthermore, the shipping process differs depending on whether the batteries are shipped by sea, air, or land, but safety always remains the top priority.

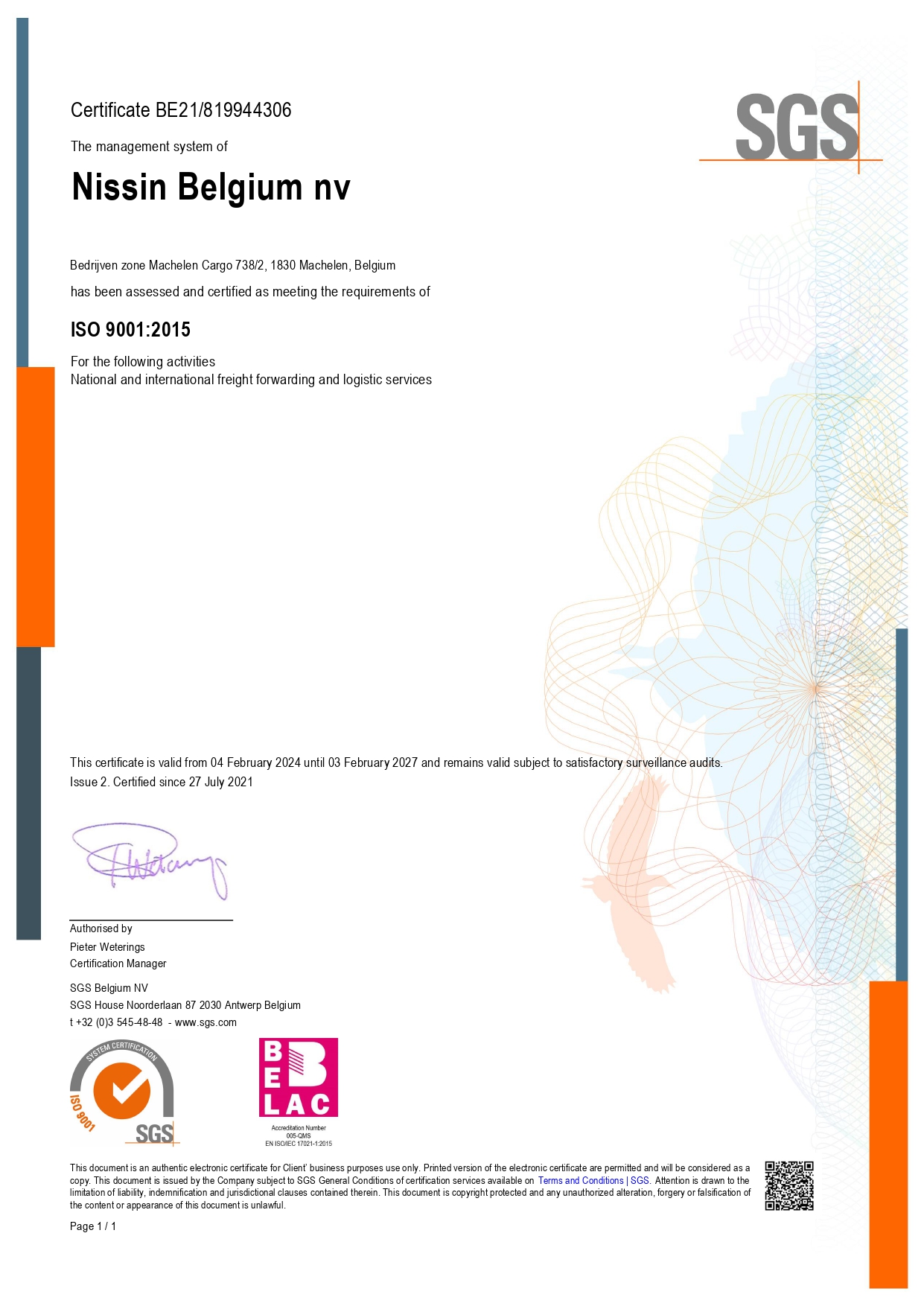

Nissin provides specialized lithium-ion battery shipping services, maintaining compliance with international safety standards and offering custom packaging solutions to safeguard your shipments.

Lithium Battery Shipping Regulations: What You Need to Know

Shipping regulations vary depending on the mode of transport and the destination. When shipping by sea, air, or land, it is essential to adhere to several rules set by organizations such as the International Air Transport Association (IATA), the International Maritime Organization (IMO), and the United Nations (UN).

International Air Transport Association (IATA) Regulations

IATA guidelines dictate that lithium-ion batteries shipped by air must meet specific packaging and labeling requirements. Batteries must be separated to avoid contact, and packaging should withstand extreme temperatures and pressure changes. Moreover, airlines impose additional restrictions based on the battery’s size and capacity.

International Maritime Organization (IMO) Guidelines

The International Maritime Organization (IMO) regulates the transport of lithium-ion batteries when shipped by sea. Shipping companies confirm that all batteries are accurately classified, securely packed, and labeled according to international standards.

Special Requirements for Packaging and Labeling Lithium-Ion Batteries

Proper packaging and labeling are important when shipping lithium-ion batteries, as these steps help prevent safety hazards during transport. Here are some key guidelines that shippers must follow:

Use UN-Approved Packaging: Lithium-ion batteries must be packaged in containers that meet United Nations (UN) standards for transporting hazardous goods. This verifies the packaging is strong enough to protect the batteries and avoid accidents during handling or transit.

Confirm Proper Insulation: Batteries must be packed to prevent them from touching each other or any conductive materials. Direct contact between batteries can lead to short circuits, which can cause overheating or even fires.

Clear Labeling: Each package containing lithium-ion batteries must be clearly labeled to show that it contains hazardous materials. This includes labels indicating lithium-ion batteries’ presence, helping handlers and transporters recognize the potential risk and handle the package accordingly.

Shipping Lithium Batteries: Step-by-Step Process

Shipping lithium-ion batteries involves meticulously meeting all regulatory and safety requirements. Below is a simplified step-by-step process for shipping these goods:

Classify the Battery Type

First, identify whether the lithium-ion battery is being shipped as part of a device, as spare batteries, or in bulk. This classification will dictate the specific regulations and packaging requirements for the shipment.

Prepare the Batteries for Shipment

Verify that the batteries are in excellent condition, with no visible damage, leaks, or swelling. They must also be packed properly to prevent them from moving during transport, and contact with other batteries or conductive materials must be avoided.

Select the Appropriate Packaging

For larger batteries or bulk shipments, use outer packaging that can absorb impact and protect the contents from external conditions. Always include cushioning materials, especially for batteries with exposed terminals.

Label and Document

Clearly label the package with all necessary information, including hazard warnings and the type of lithium-ion battery. Prepare the proper documentation, such as the Dangerous Goods Declaration (DGD), to accompany the shipment. This is especially important when shipping across international borders.

Coordinate with the Carrier

Finally, coordinate with the shipping carrier to confirm they are aware of the nature of the cargo and are equipped to handle goods. Working with certified carriers is essential for safe delivery.

Smart Shipping for Lithium-Ion Batteries with Nissin Belgium

Shipping lithium-ion batteries can be tricky due to the safety risks involved, but Nissin Belgium makes the process easier. As an expert in handling dangerous goods, including lithium-ion batteries, Nissin follows all international safety rules and offers complete logistics solutions so your shipments arrive safely and on schedule.

Nissin’s Key Services for Battery Shipping Include:

Custom Packaging Solutions: Nissin designs packaging that meets United Nations (UN) regulations, keeping your batteries safe during transit. This reduces the risk of damage or incidents along the way.

Compliance with Global Regulations: Nissin keeps up-to-date with international shipping laws, including International Air Transport Association (IATA) and International Maritime Organization (IMO) guidelines, ensuring your shipments meet all safety requirements, regardless of the destination.

Personalized Logistics Support: Whether shipping by air, sea, or land, Nissin adjusts its logistics services to fit your specific needs, offering flexible solutions for your shipping requirements.

Constant Shipment Tracking: With status updates, you can stay informed throughout the shipping process and monitor your shipment from start to finish.

Final Thoughts on Battery Shipping

Shipping lithium-ion batteries is more complex than moving everyday items, but safe and compliant transport offers immense rewards. With the right knowledge of regulatory requirements, strict adherence to packaging and labeling guidelines, and a well-defined shipping process, you can confirm your batteries arrive safely.

No matter the transport mode, be it sea, air, or land – compliance with international regulations is essential to prevent costly delays, penalties, and safety risks.

Partnering with trusted leaders like Nissin provides peace of mind for safely transporting lithium-ion batteries. Our professional team is dedicated to managing your shipments with the utmost care. Allow us to streamline your shipping process for secure and reliable delivery.

Contact us at + 32 2 751 44 99 or write an email to HowCanIHelpYou@be.nissin-eu.com with your requirements.