Rail transportation plays a key role, facilitating the efficient movement of goods across vast distances. From raw materials to finished products, efficient transportation of these goods is a crucial component of a thriving economy. Among the myriad options available, various rail freight cars emerge as a reliable and economical solution for hauling commodities. However, like any mode of transportation, each rail freight car type presents its pros and cons, requiring careful consideration to optimize the shipping process.

Choosing the appropriate train freight car is a critical decision that can significantly impact operational costs, transit times, and the overall effectiveness of the supply chain. By understanding the strengths and weaknesses of various freight car types, businesses can make informed choices and leverage the advantages that best align with their specific transportation needs.

The Different Types of Rail Freight

Boxcars

Boxcars are the most recognizable types of rail freight car. These enclosed rectangular cars offer maximum protection from the elements and security for your cargo. They’re ideal for transporting dry, palletized goods like machinery, electronics, and consumer products.

Pros:

Secure and weatherproof

Versatile for various palletized goods

Large capacity

Cons:

Not suitable for bulk materials

Loading and unloading can be time-consuming

Hopper Cars

Hopper cars are designed for bulk commodities like grain, coal, and sand. These open-top cars feature hopper doors at the bottom for easy unloading. Some variations include covered hoppers for weather-sensitive materials like fertilizer or plastics.

Pros:

Efficient loading and unloading of bulk materials

Suitable for heavy cargo

Some variants offer weather protection

Cons:

Not ideal for bagged or palletized goods

Can be susceptible to product loss during transit

Tank Cars

Tank cars are cylindrical steel containers mounted on a railcar frame. They are specifically designed to transport liquids like oil, chemicals, and food products. They have specialized linings and pressurization systems to ensure safe and secure transport.

Pros:

Secure and leak-proof for liquid cargo

Some variations are temperature-controlled for sensitive products

Cons:

Limited to transporting liquids

Require specific loading and unloading facilities

Flatcars

Flatcars are open-frame cars ideal for oversized or odd-shaped cargo that wouldn’t fit inside a boxcar. They can be secured with straps or chains for safe transport. Examples of goods transported on flatcars include construction equipment, vehicles, and large machinery.

Pros:

Versatile for oversized or odd-shaped cargo

It can be loaded from multiple sides

Cons:

No weather protection for cargo

Requires secure fastening of the load

Choosing the Right Rail Freight Car

Selecting the optimal freight car hinges on your specific commodity. Here are some key factors to consider:

The type of commodity: Boxcars are ideal for dry goods, while tank cars are necessary for liquids.

Weight and dimensions: Ensure the car’s capacity can accommodate your cargo’s weight and size.

Protection needs: Does your cargo require weather protection or temperature control?

Loading and unloading facilities: Consider the availability of specialized equipment for specific car types.

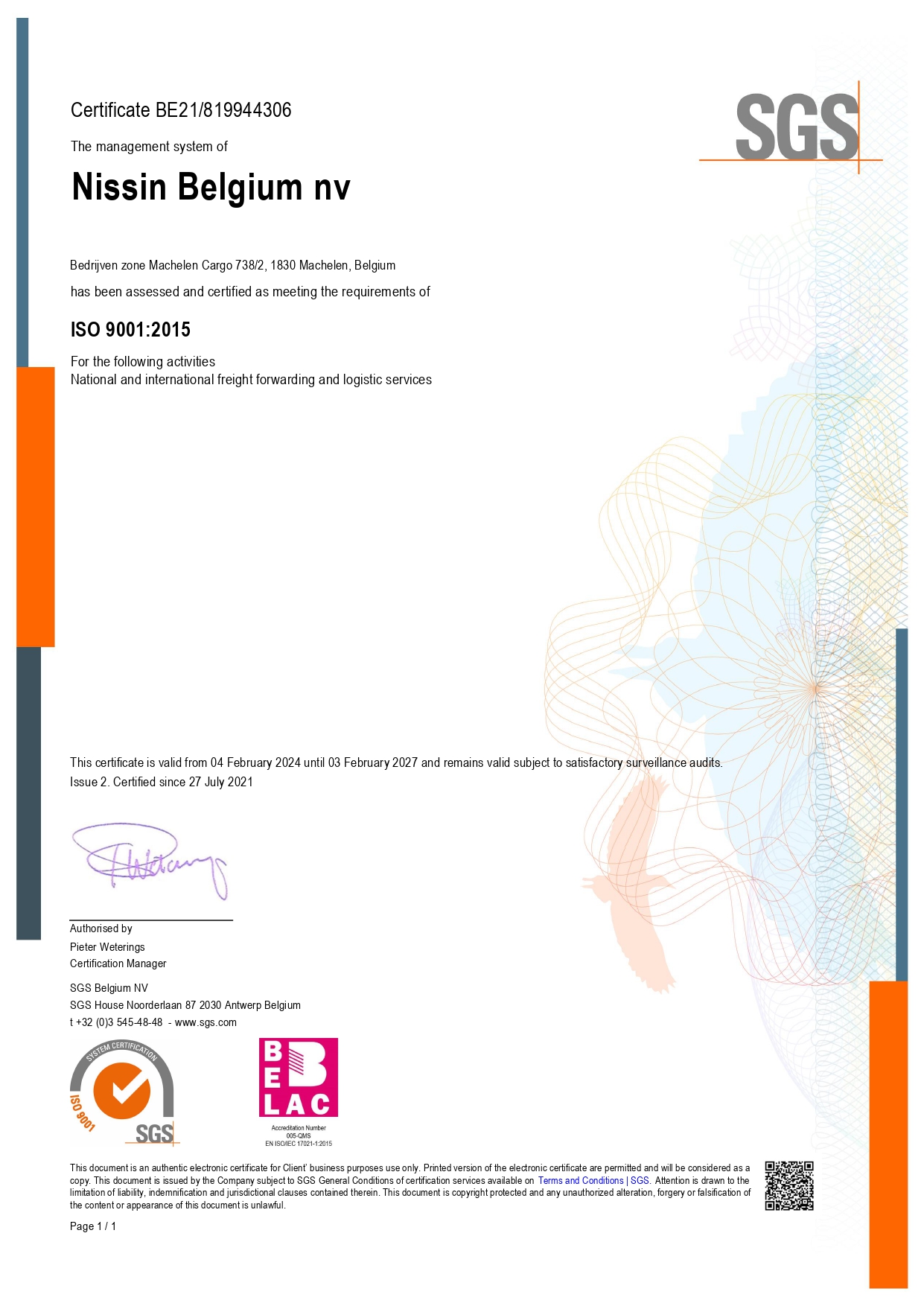

Get Your Rail Freight Rolling with Nissin Belgium

As businesses navigate the complexities of train freight transportation, partnering with a reliable logistics provider like Nissin Belgium can be a game-changer. Our team of experienced logistics specialists can help you choose the most suitable freight car for your specific needs. We have a vast network of partners across the globe, ensuring efficient and cost-effective transportation of your cargo.

To discuss your logistics requirements, contact us at + 32 2 751 44 99 or write to us at HowCanIHelpYou@be.nissin-eu.com