Transporting perishable goods across vast oceanic distances requires efficient transportation and strict adherence to temperature-sensitivity protocols. Reefer containers, or refrigerated containers, are essential for the modern supply chain because they ensure the secure and dependable delivery of perishable cargo. Whether it’s fresh produce or pharmaceuticals, these specialized units are crucial for maintaining the quality and integrity of goods during transit, emphasizing the significance of thorough reefer container inspection.

Why Ocean Freight?

For many industries, ocean freight has become the preferred mode of transportation for refrigerated containers. Maritime logistics’ sheer scale and efficiency allow for the cost-effective movement of large volumes of goods over vast distances. Additionally, advancements in reefer technology have made it possible to maintain the integrity of temperature-sensitive cargo even during extended voyages.

Ocean Freight vs. Air Freight

While air freight offers unparalleled speed, ocean freight’s cost-effectiveness and environmental sustainability make it the more attractive option for many businesses. Refrigerated containers can reliably preserve the quality of perishable goods during the longer transit times associated with maritime transport, making it a viable and often preferred choice for international logistics.

Types of Reefer Containers

Reefer containers come in various sizes and designs to accommodate diverse cargo requirements.

Dry Containers: These maintain consistent chilled temperatures for general produce and flowers.

Frozen Containers: These containers have powerful refrigeration systems and are designed for items requiring sub-zero temperatures, like frozen meat or seafood.

Super Freezer Containers: The ultimate in cold storage, these containers can have temperatures down to -80°C, perfect for highly delicate items or scientific samples.

How to Maintain a Reefer Container?

Regular maintenance is key to extending the lifecycle and ensuring the continued efficiency of a refrigerated shipping container. This includes:

Cleaning and Sanitation: After each use, the container’s interior must be thoroughly cleaned and sanitized to prevent mould growth.

Regular Servicing: Scheduled maintenance ensures the smooth operation of the refrigeration unit, minimizing the risk of breakdowns during transport.

Parts Replacement: Worn-out components like gaskets and filters should be replaced on time to maintain optimal performance.

Documentation: Meticulous record-keeping is important for effective container maintenance. This includes documenting inspection findings, maintenance performed, and any repairs undertaken.

How to check container condition?

Pre-Trip Inspection: Before each voyage, a thorough visual inspection is conducted to identify potential issues with the container’s body, doors, and gaskets. This ensures a watertight seal and prevents damage to the cargo.

Refrigeration System Check: The functionality of the refrigeration unit is meticulously evaluated. Technicians verify temperature control accuracy, refrigerant levels, and overall system health.

How are containers inspected?

Temperature Monitoring: Throughout the journey, temperatures within the container are continuously monitored and documented. This ensures that the cargo remains within the optimal temperature range.

Airflow Verification: Proper air circulation is important for maintaining consistent temperatures within the container. Technicians inspect the airflow system to ensure unobstructed pathways for cool air.

The Importance of Ocean Freight Container Tracking

In today’s interconnected world, real-time tracking of refrigerated containers is important. Advanced tracking systems allow shippers, consignees, and logistics providers to monitor the location and temperature of the container throughout its journey, providing peace of mind and ensuring timely intervention if any issues arise.

Partnering with Nissin Belgium for Unparalleled Reefer Logistics

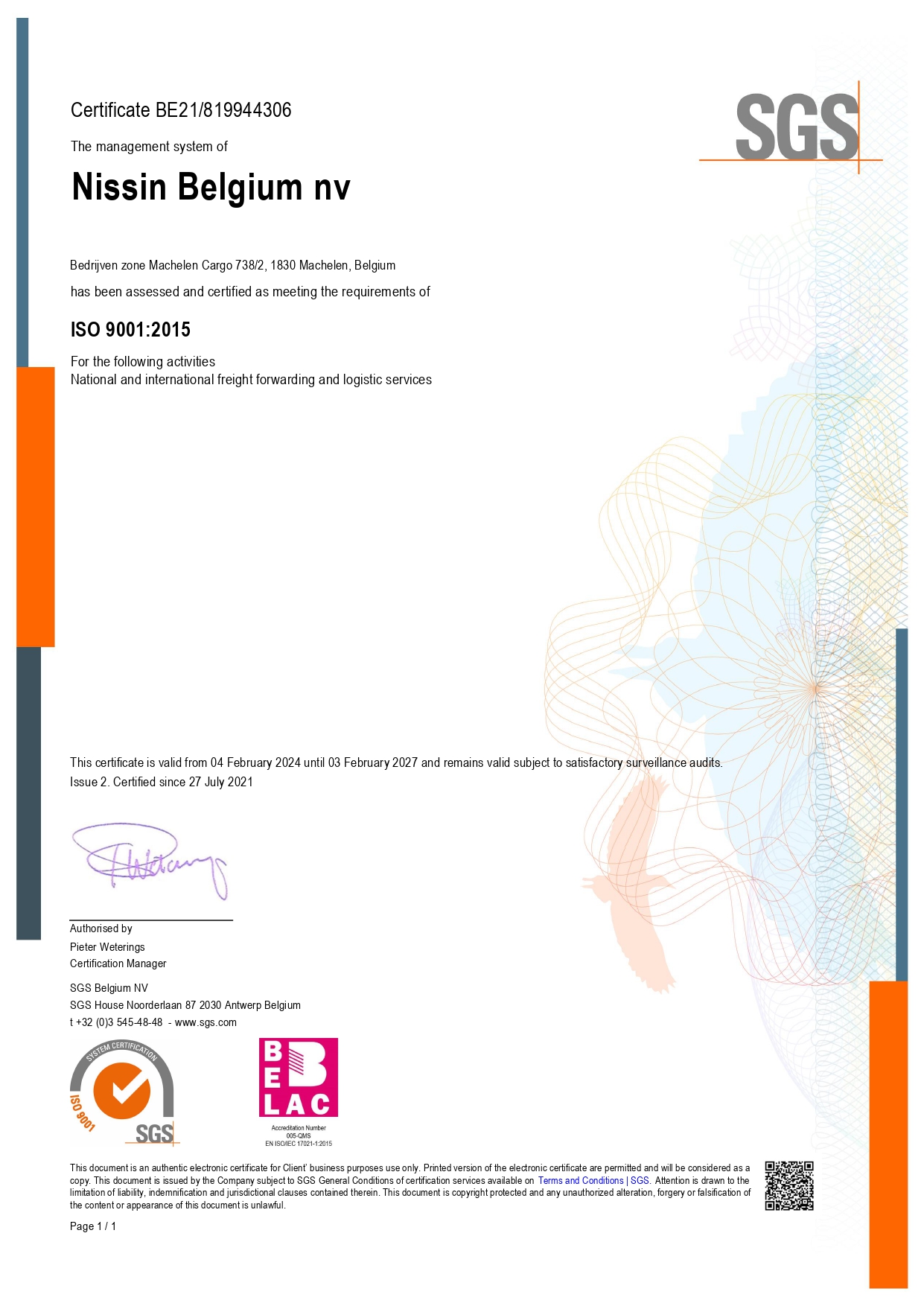

Logistics providers can ensure the reliable and efficient transportation of temperature-sensitive goods by adhering to these meticulous reefer container inspection and maintenance processes. Whether you’re shipping fresh produce, pharmaceuticals, or any other perishable cargo, partnering with a trusted freight forwarding company like Nissin Belgium can provide the peace of mind and expertise needed to navigate the complexities of global logistics.

The seamless delivery of perishable goods across continents hinges on the intricate dance between meticulously maintained refrigerated shipping containers and expert logistics providers. By partnering with a reliable freight forwarding company like us, you can ensure that your temperature-sensitive cargo reaches its destination fresh, safe, and on time.

We boast extensive experience in container management, offering a comprehensive suite of services encompassing inspection, maintenance, and real-time container tracking, providing you with complete peace of mind throughout your journey.

Contact us at + 32 2 751 44 99 or write HowCanIHelpYou@be.nissin-eu.com to discuss your logistics needs.