As businesses strive for operational excellence, efficient warehouse inventory management has never been more critical.

So, how can you ensure your warehousing strategies are up to date? Explore the core principles, benefits, future trends, and more of effective warehouse inventory management to keep your operations running smoothly and competitively.

What is Warehousing Inventory Management (WIM)?

Warehousing Inventory Management (WIM) System involves systematically overseeing and controlling inventory within a warehouse. This includes tracking stock levels, managing orders, and ensuring efficient storage. Effective management minimizes costs, meets customer demands, and streamlines operations. As a result, it is a critical component of successful warehousing practices.

Why is a Warehousing Service Important in Logistics?

Warehouse services are central to logistics, providing a strategic location for storing goods. They streamline supply chains to ensure timely product availability and reduce transportation costs. Beyond that, they help improve inventory handling to meet customer demands efficiently.

Top Best Practices for Inventory Management

Adhering to best practices ensures smooth and efficient warehousing operations. Key methods include:

Implement Real-Time Tracking Systems: Use advanced software and barcode scanning technology to monitor inventory levels in real-time. For example, systems like Radio Frequency Identification (RFID) and Internet of Things (IoT) sensors can provide accurate and instant stock movement data, helping avoid overstocking or stockouts.

Optimize Warehouse Layout: Design your warehouse layout for efficiency by organizing products based on their demand and picking frequency. For instance, place high-turnover items closer to packing and shipping areas to speed up picking.

Regularly Review and Update Inventory Levels: Conduct periodic audits and adjust inventory levels based on current data and trends. Implement cycle counting to ensure that inventory records are accurate and discrepancies are addressed promptly.

Adopt Automation and Robotics: Integrate automation solutions such as conveyor systems and robotic pickers to streamline repetitive tasks. For example, automated guided vehicles (AGVs) can transport goods across the warehouse, reducing manual labour and increasing accuracy.

Enhance Supplier and Customer Communication: Maintain clear communication channels with suppliers and customers to ensure timely deliveries and address potential issues. Collaborative platforms can help share real-time information and forecasts.

Implement Data-Driven Decision-Making: Use analytics and reporting tools to gain insights into inventory trends and performance. Data-driven decisions, such as adjusting reorder points based on historical sales data, can improve inventory management efficiency.

Prioritize Staff Training: Ensure warehouse staff are trained on the latest inventory management practices and technologies. Regular training helps improve operational efficiency and reduces errors in inventory handling.

5 Benefits of Warehouse Inventory Management

Improved Accuracy: Reliable tracking reduces errors in stock levels and order fulfilment, ensuring accurate inventory records and meeting customer demands.

Cost Reduction: Efficient management minimizes excess inventory and associated holding costs, optimizing cash flow.

Enhanced Customer Satisfaction: Accurate and timely order fulfilment leads to faster delivery and improved service.

Optimized Space Utilization: Effective management maximizes warehouse space for more efficient storage and retrieval.

Streamlined Operations: Automation and data-driven insights reduce manual work and improve overall efficiency.

What is the Future of Warehouse Management?

The future of warehouse management is shaped by technological advancements and evolving consumer demands. Automation and robotics enhance operational efficiency, while artificial intelligence (AI) aids in predictive analytics and inventory optimization. With the rise of e-commerce, warehouses will adapt by focusing on faster delivery, localized facilities, and integrating drones and autonomous vehicles for last-mile logistics.

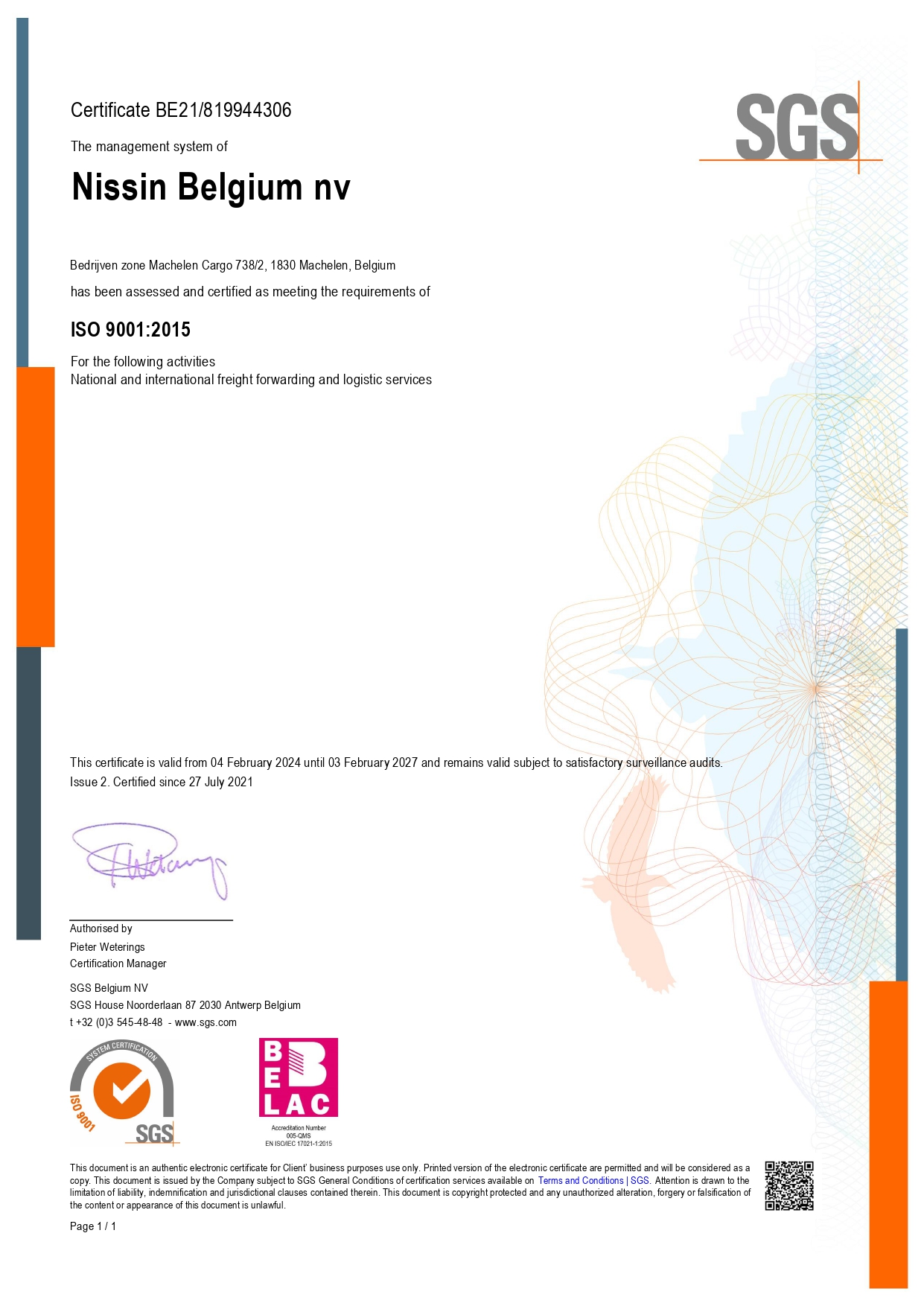

Nissin Belgium: Warehousing Experts at Your Service

Nissin Belgium stands out in the warehousing industry with its extensive expertise in providing customized warehousing solutions. Our team specializes in creating efficient, scalable systems that address common inventory management challenges, such as optimizing space and improving stock accuracy.

Contact us at + 32 2 751 44 99 or write an email to HowCanIHelpYou@be.nissin-eu.com with your requirements.